Wheel lug nuts are fastener, used for securing wheels attached the hub. The wrong size can lead to a host of problems, from minor inconveniences to major safety concerns. Here’s what you need to know about how do I konw what lug nut size for my vehicle.

Check Your Wheel's Lug Size

Please take necessary mearuements of your current wheel nuts. The common lug nut specifications include overall length, thread pitch and hex size.

Length:

Minimum Length: The lug nut needs to have enough thread engagement with the stud to securely hold the wheel.

Too Short: Can lead to the lug nut bottoming out on the stud before properly tightening the wheel.

Too Long: Can cause issues with wheel clearance or interfere with other components.

How to find it: Measure the exposed shank length of the lug bolt when mounted on the wheel, ensuring it's sufficient for the wheel and hub.

Thread Size and Pitch:

Thread Size: The diameter of the wheel stud, often measured in millimeters (e.g., 12mm, 14mm) or inches (e.g., 1/2", 9/16").

Thread Pitch: The distance between the threads on the stud, usually expressed as a number (e.g., 1.25mm, 1.5mm).

General Expressions: m14x1.5 lug nuts,14x1 5 lug nuts or 14mm x 1.5 lug nuts.

How to find it: Use calipers or a thread gauge to measure the stud's diameter and pitch, or consult your vehicle's owner's manual.

Hex Size:

Tool Size: The hex size (measured across the flats of the lug nut) determines the wrench or socket needed for installation and removal.

Common Sizes: 17mm, 19mm, and 21mm are common, but others exist.

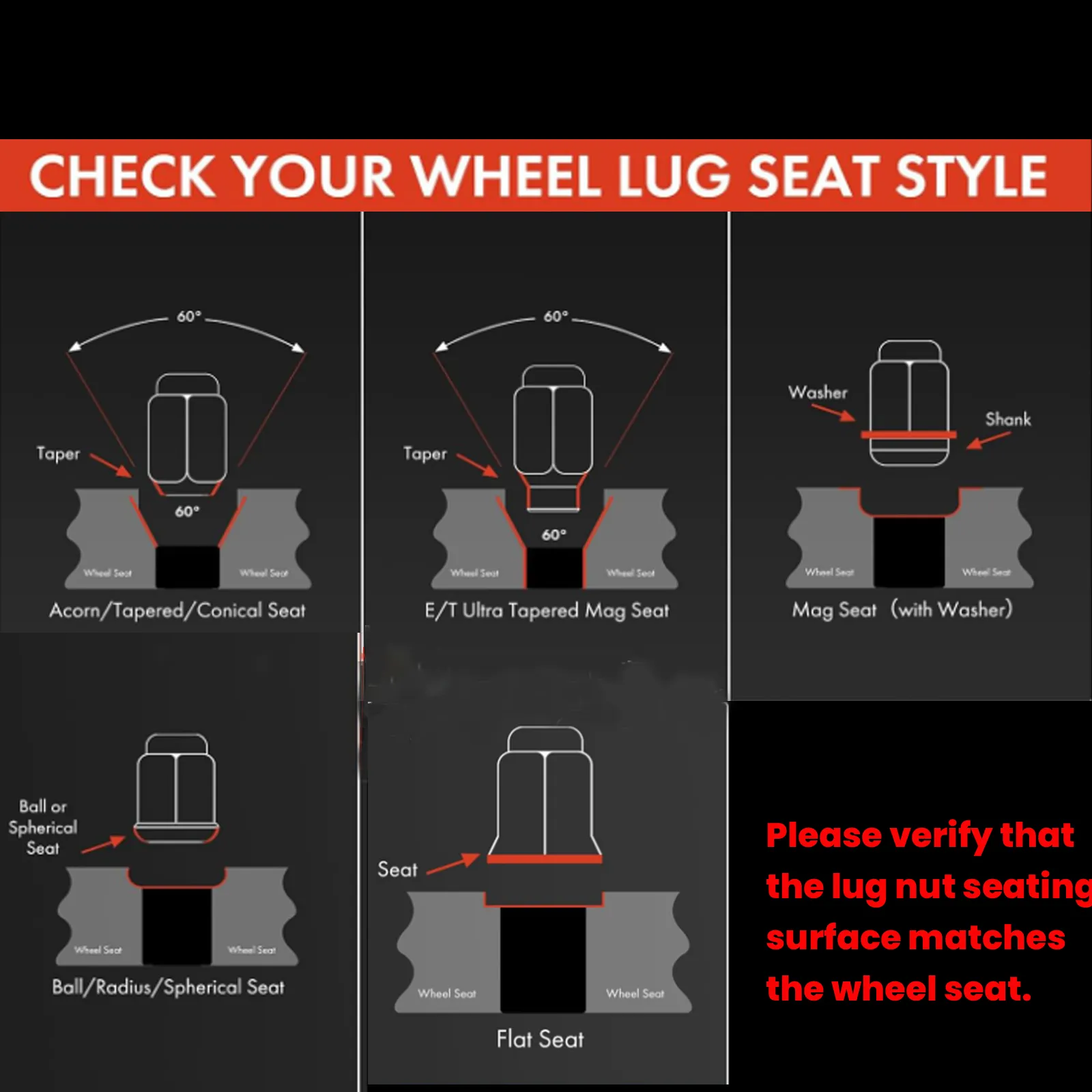

Check Your Wheel's Lug Seat

Please verify that the lug nut seating surface matches the wheel seat. The common seat style includes flat seat, mag seat, acorn/conical seat, ball seat.

Seat Type:

Acorn/Tapered Seat: Most common for aftermarket wheels.

Mag Seat: Features a flat seating surface with a separate washer.

Ball Seat: Used on some original equipment wheels.

Matching the correct lug nut/bolt seat to wheel seat is a very important safety precaution. It can help to avoid lugs loosening, wheel vibration and/or damage to your vehicle.

Installing Lug Nuts Suggestion:

-Installed in alternating pattern

-Lug nuts must be installed in alternating pattern, commonly referred to as a starpattern. This ensured a nunfirm distribution of load across the wheel mountingsurface.

-Not recommended to use Impact Wrench

Electric impact wrenches which may apply excessive torque to damage the surface coating! We recommend you to use hand wrench.